Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Algae Protein Snack Bars Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing an algae protein snack bars plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

There has been a marked increase in consumer awareness regarding the health benefits of algae-based products, including snack bars. Algae, especially varieties like spirulina and chlorella, are known for their exceptional nutritional profiles, which include high protein content, essential vitamins, minerals, antioxidants, and omega-3 fatty acids. For instance, spirulina contains about 52-80% protein by dry weight, making it a potent source of plant-based protein, while chlorella offers 50-60% protein and is rich in all nine essential amino acids. In terms of vitamins and minerals, spirulina provides approximately 0.2-0.4 mg of Vitamin B12 per 100 grams, which is crucial for vegetarians and vegans, along with 62-115 mg of iron per 100 grams.

Chlorella delivers around 287% of the daily value for Vitamin A and about 202% of the daily value for iron per serving. This awareness surrounding the nutritional benefits has led consumers to seek out nutrient-rich foods that enhance their overall well-being. The trend towards healthier snacking options has seen a surge in the consumption of algae-based snacks. Additionally, as environmental concerns rise, consumers increasingly favour sustainable food sources. Algae cultivation requires significantly less water and land compared to traditional agriculture, providing a sustainable ingredient to food manufacturers.

Other elements to consider while establishing an algae protein snack bars plant include raw material sourcing, workforce planning, and packaging. The production of algae protein snack bars relies on microalgae species including Spirulina and Chlorella. Other ingredients may include natural sweeteners, nuts, and grains, which complement the algae to create a balanced and appealing snack option.

Moreover, to help stakeholders determine the economics of an algae protein snack bars plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

Algae protein snack bars are a nutritious food option made from algae, particularly microalgae like Spirulina, which is rich in protein and essential nutrients. These bars have gained popularity as a healthier snack choice, particularly in recent years as consumers seek alternatives to traditional protein sources. The use of algae in food products dates back centuries, but the modern incorporation of algae into snack bars began gaining traction in the early 2000s, driven by increasing awareness of the health benefits and environmental sustainability of algae.

Algae protein snack bars typically weigh between 30 to 60 grams and have a texture that can range from chewy to crunchy. They often contain 10-15% algae protein, which contributes to a protein content of about 12-20 grams per bar. The bars may also have a moisture content of around 5-10%, which ensure they remain shelf stable. Chemically, algae protein is approximately 80-85% pure, containing around 32% essential amino acids, which makes it a complete protein source. Additionally, the bars are rich in vitamins (such as B12), minerals (including iron and calcium), and antioxidants, which contribute to their health benefits. The incorporation of algae also enhances the fibre content, providing about 3-5 grams per bar, thereby promoting digestive health.

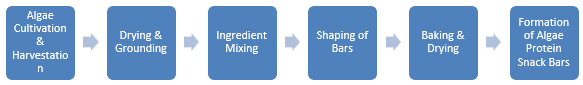

The production process of algae protein snack bars begins with algae cultivation, where microalgae, such as Spirulina or Chlorella, are grown in controlled environments, typically in large tanks or ponds. Once the algae reach optimal growth, they are harvested to collect the biomass. The harvested algae undergo processing, where they are dried and ground into a fine powder. This algae powder serves as the primary protein source for the snack bars. Next, the ingredient mixing stage combines the algae powder with other components, such as nuts, seeds, sweeteners, and flavourings, to enhance taste and texture. The mixture is then shaped into bars during the forming bars step, where specialised equipment presses the combined ingredients into the desired bar shape. After forming, the bars may undergo baking or drying to achieve the right texture and moisture content, ensuring they remain shelf stable. Following this, quality control measures are implemented to inspect the bars for nutritional content and safety standards. Finally, the finished bars are packaged for distribution to retailers.

The algae protein snack bar market is driven by several factors, including the rising demand for plant-based and sustainable protein sources. As consumers increasingly adopt health-conscious diets, algae protein bars are gaining popularity due to their high nutritional value, which includes essential amino acids, vitamins, and minerals. These bars serve a wide range of applications, appealing to fitness enthusiasts, vegans, and individuals seeking nutrient-dense snacks. Brands like Ocean's Halo and Kuli Kuli offer algae-based snack bars that cater to these consumer demands. Additionally, growing awareness of the environmental benefits of algae cultivation, which requires fewer resources compared to traditional protein sources, further propels market growth.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

A detailed overview of production cost analysis that evaluates the manufacturing process of algae protein snack bars is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. For instance, innovations in food technology have improved the taste and texture of algae-based products, increasing their demand among consumers. Snack manufacturers are experimenting with new formulations to enhance sustainability in food production. In November 2024, Brevel implemented a pioneering model for producing microalgae protein, which uses a fermentation process to boost protein level in the final product by 70% while using 90% less land and 80% less water compared to traditional animal protein sources. This initiative addresses the growing demand for alternative proteins and improves appeal of algae protein based snacks market.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for an algae protein snack bars production plant:

Market Dynamics and Trends: The rise in veganism and flexitarian diets is significantly impacting market conditions in the algae protein snack bars sector, as consumers are reducing their intake of animal products due to health concerns and ethical considerations regarding animal welfare. As of 2024, approximately 4.7% of UK adults identify as vegan, which translates to over 2.5 million individuals. In the United States, about 2% of the population follows a vegan diet, where 60% of Generation Z and millennials are reported to be vegetarians or flexitarians.

The global movement towards plant-based diets is further evidenced by the participation in initiatives like Veganuary, which saw a record-breaking 25 million participants in 2024. As consumers become more aware of the ethical implications of animal agriculture and its environmental impact, they are actively seeking sustainable alternatives like algae protein snacks. This shift not only reflects changing dietary preferences but also signals a broader commitment to healthier lifestyles and ethical consumption patterns. Understanding these trends helps businesses align their production plans in the algae protein snack bars market.

Profiling of Key Industry Players: Leading manufacturers like Brevel and Corbion are included in the algae protein snack bars report. Recently, Brevel inaugurated its first commercial facility in June 2024, designed to produce hundreds of tons of microalgae protein. Corbion has partnered with Nestlé to develop innovative microalgae-based ingredients aimed at enhancing the nutritional profile of plant-based products. Brands like Algi Foods are also offering a range of algae-based snack bars. Its ‘Impact Cocoa and Cacao bar’ is made entirely from algae and other natural ingredients. Manufacturers looking to enter in this market can leverage these strategies to capture a growing market share.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in algae protein snack bars prices are influenced by several key factors, particularly the costs of essential raw materials such as microalgae (e.g., spirulina and chlorella). The production costs of these algae can vary significantly based on cultivation methods, with factors like land, water usage, and energy costs playing a critical role. The quality and sourcing of ingredients, such as whether they are organic or sustainably harvested, can lead to higher prices, affecting market dynamics.

Establishing an algae protein snack bars manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

The establishment of an algae protein snack bars manufacturing facility must comply with various regulatory frameworks that govern production standards. Key regulations include the Novel Food Regulation (EU) 2015/2283, which mandates pre-market authorization for products not significantly consumed in the EU before May 15, 1997, such as certain microalgae. Additionally, manufacturers must adhere to food safety standards set by organisations like the Food Safety and Standards Authority of India (FSSAI), which outlines permissible limits for moisture, protein content, and contaminants in food products. Compliance with these regulations not only ensures legal operation but also enhances product safety and marketability.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the algae protein snack bars industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share