Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Acid Washed Granulated Activated Carbon Manufacturing Plant Project Report 2025 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing an acid washed granulated activated carbon plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

In 2024, stringent environmental regulations regarding air and water pollution control are driving the demand for activated carbon. Governments worldwide are implementing stricter standards to limit emissions of hazardous pollutants, including mercury. The U.S. Environmental Protection Agency (EPA) has established Mercury and Air Toxics Standards (MATS), which mandate significant reductions in mercury emissions from coal-fired power plants. This regulation necessitates the use of activated carbon for effective mercury capture, leading to increased consumption of acid washed granulated activated carbon in industrial applications. Additionally, many countries are enforcing regulations that require cement producing industries to adopt eco-friendly technologies for waste treatment and emissions control. This is prompting manufacturers to invest in advanced filtration systems that use activated carbon, thereby enhancing its market presence.

Other elements to consider while establishing an acid washed granulated activated carbon plant include raw material sourcing, workforce planning, and packaging. The production of acid AWGAC relies on coconut shells, wood, coal, and various biomass materials. Coconut shells are favoured for their high carbon and low ash content, which, combined with the activation process, results in a highly porous material ideal for adsorption. Wood-based activated carbon is valued for its availability and cost-effectiveness and different wood types can yield varying characteristics. Coal serves as a widely used source due to its economic benefits and availability. Additionally, biomass materials such as nutshells from other fruits, paper mill waste, and agricultural residues are used due to their lower environmental impact. The choice of raw materials determines the quality and performance of AWGAC.

Moreover, to help stakeholders determine the economics of an acid washed granulated activated carbon plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

However, recent natural disasters have impacted the availability of coconut shells in key producing countries like the Philippines and Indonesia, leading to price volatility. To combat this, companies like Calgon Carbon have expanded their sourcing strategies to include alternative materials and suppliers to reduce dependency on specific regions. Additionally, Jacobi Carbons has invested in local production facilities in various markets to enhance supply chain resilience and reduce transportation costs. These strategies can effectively mitigate supply chain risks and ensure a more stable supply of AWGAC to meet growing industrial needs.

Acid washed granulated activated carbon (AWGAC) is a specialised form of activated carbon treated with acid to enhance its purity and adsorption capabilities. This process removes impurities and reduces ash content, making it ideal for applications in water purification, food processing, and pharmaceuticals. The history of AWGAC began in the mid-20th century when the demand for high-purity materials in industrial processes increased, leading to the development of acid-washing techniques to improve activated carbon performance. Today, acid washed granulated activated carbon is widely used in water treatment, food and beverage processing, and pharmaceuticals industries.

AWGAC has a high surface area, typically exceeding 900 mg/g for iodine adsorption, and a neutral pH range of 6.5 to 8.0, which is suitable for various applications. It has low ash content (often below 1.5%) and minimal heavy metal leachability due to the acid washing process. The granulated form also provides excellent flow characteristics. Additionally, it has high hardness, ensuring longer operational life.

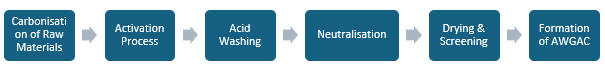

The production of acid washed granulated activated carbon begins with carbonisation, where raw materials such as coal or coconut shell are heated in the absence of oxygen. This process removes non-carbon elements. The next step is activation, which typically uses steam or chemicals to create a highly porous structure with a large surface area. Following activation, the carbon undergoes acid washing. This step involves treating the activated carbon with an acid, such as hydrochloric acid (HCl), to remove impurities, reduce ash content, and lower the pH to a neutral range. After acid washing, the carbon is neutralised with a base, such as sodium hydroxide (NaOH). The carbon is then dried to remove moisture, followed by screening to obtain the desired granular size fraction. Finally, the processed granulated activated carbon is packaged for distribution.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

Below is a detailed overview of the processes involved in the production of acid-washed granulated activated carbon:

1. Carbonisation of Raw Material

The raw materials, typically coconut shells, coal, or wood, are subjected to high temperatures in an oxygen-free environment. This process decomposes the raw material into a char, removing volatile components such as water, tars, and gases.

General Reaction:

C6H10O5 (biomass) → C (char) + H2O + CO2 + other volatile compounds (heating in the absence of oxygen)

2. Activation Process

In this step, the char is exposed to an oxidising gas, typically steam or carbon dioxide, at high temperatures (800-1000°C). The activation process increases the surface area and develops the porous structure of the carbon.

Chemical Reactions:

1. Steam Activation:

C (char) + H2O (steam) → CO + H2

C (char) + CO2 → 2 CO (g)

3. Acid Washing

The activated carbon is washed with acids such as hydrochloric acid (HCl) to remove any remaining impurities, such as metal oxides. This process improves the purity of the activated carbon and prepares it for its final applications.

Chemical Reaction:

Metal oxides (impurities) + HCl → Metal chloride (soluble) + H2O

4. Granulation and Drying

The acid-washed activated carbon is then granulated to the desired particle size. After granulation, the product is dried to remove any residual moisture, ensuring the final product meets industry standards.

Acid washed granulated activated carbon is widely used in various industries, including water treatment, food and beverage processing, pharmaceuticals, and electronics manufacturing. Its applications include dechlorination, removal of organic compounds, and improving water taste and odour. The market for acid washed granulated activated carbon is driven by the increasing demand for clean water and safe food products, as well as stringent regulations regarding contaminants in industrial processes. For example, acid washed granular activated carbon is essential in reverse osmosis systems to protect membranes from fouling and in the semiconductor industry for ultra-pure water applications.

A detailed overview of production cost analysis that evaluates the manufacturing process of acid washed granulated activated carbon is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. For instance, in 2023, global coal production reached approximately 8,694.9 million tons, with China leading as the dominant producer, accounting for over 50% of the total output at around 4,362.1 million tons. India followed as the second-largest producer, increasing its output to nearly 968.8 million tons, a growth of about 12% from the previous year. Indonesia and the United States produced approximately 781.3 million tons and 728.4 million tons, respectively. Other notable producers included Australia with 554.8 million tons, Russia at 423.1 million tons, and South Africa with 277.9 million tons.

Similarly, in 2023, India exported approximately 141,862 tons of activated carbon, with the U.S. being the largest importer at 14% of these exports. Sri Lanka exported 51,539 tons in 2023, marking a 6% decline from 2022; however, early 2024 showed a recovery with a 30% increase in exports compared to the previous year. This abundance of coal and coconut shells supports the activated carbon industry by providing a readily available raw material for manufacturing. Manufacturers will benefit from increased production capacity, enabling them to meet the growing need for clean water. This heightened output can lead to economies of scale, potentially reducing production costs and increasing profit margins.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for an acid washed granulated activated carbon production plant:

Market Dynamics and Trends: Factors such as increasing demand for clean and drinkable are influencing market conditions in the acid washed granulated activated carbon sector. As of 2024, approximately 4.4 billion people globally lack access to safely managed drinking water, highlighting a significant public health crisis. Unsafe drinking water contributes to waterborne diseases, with at least 1.7 billion people using sources contaminated with feces. In terms of wastewater treatment, while 76% of total wastewater generated receives some treatment, only 60% of this is processed safely. This gap underscores the urgent need for effective water treatment solutions. In India, groundwater contamination affects millions, particularly in states like Rajasthan and Assam, where harmful substances complicate access to clean water. This drive the increasing demand for acid washed granulated activated carbon, which is essential for removing contaminants from both drinking water and wastewater. Understanding these factors helps businesses align their production plans.

Profiling of Key Industry Players: Leading manufacturers of acid washed granulated activated carbon (AWGAC) include CG Carbon, Raj Carbon, and Jay Maa Bhavani Chemicals. CG Carbon offers high-quality products for municipal water treatment and air purification. Raj Carbon, with a capacity of 50 metric tons per day, focuses on meeting stringent water quality standards. These companies are pivotal in providing sustainable filtration solutions that comply with increasing environmental regulations.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in acid washed granulated activated carbon (AWGAC) prices are influenced by several key factors, particularly the costs of essential raw materials such as coconut shells and coal. In 2023, the price of coconut shell charcoal ranged from approximately USD 349 to USD 461 per metric ton, with early 2024 indicating a potential upward trend in prices due to increased demand, particularly from India and Sri Lanka.

Coal prices have also experienced notable fluctuations. As of late 2023, thermal coal prices were around USD 130 per metric ton, with projections indicating a decline of over 20% in 2024. However, this decline is tempered by strong demand from countries like China and India, which could influence future pricing. Overall, these trends in coconut shell and coal prices significantly impact the production costs of AWGAC, contributing to its market volatility.

Establishing an acid washed granulated activated carbon manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the acid washed granulated activated carbon industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 2,699

USD 2,429

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 3,699

USD 3,329

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 4,799

USD 4,079

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 2,699

USD 2,429

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 3,699

USD 3,329

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 4,799

USD 4,079

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Our step-by-step guide will help you select, purchase, and access your reports swiftly, ensuring you get the information that drives your decisions, right when you need it.

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City,1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

United States

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

United States (Head Office)

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City, 1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

Share