Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Acai Berry Freeze Dried Packs Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing an acai berry freeze-dried packs plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The demand for acai berry based products is increasing because of consumer shift towards healthier food items. Acai berries are known for their high antioxidant content, which is critical for combating oxidative stress and reducing the risk of chronic diseases. Acai berries have an ORAC (Oxygen Radical Absorbance Capacity) score of 15,405 per 100 grams, significantly higher than blueberries, which score only 4,669. This high antioxidant level is attributed to compounds such as anthocyanins, which are known to protect cells from damage caused by free radicals.

Studies indicate that regular consumption of acai may help lower LDL (bad) cholesterol levels. One study involving 10 overweight adults who consumed acai smoothies twice daily for a month showed a notable reduction in both total and LDL cholesterol levels. This suggests acai can improve heart health by lowering cholesterol and improving blood sugar levels, making it a popular choice among health-conscious consumers.

Other elements to consider while establishing an acai berry freeze-dried packs plant include raw material sourcing, workforce planning, and packaging. The primary raw material for freeze-dried packs is the acai berry itself, which is harvested from the acai palm tree (Euterpe oleracea) native to the Amazon rainforest. These berries are known for their high antioxidant content, particularly anthocyanins, which can be up to 30 times higher than that of red wine. To produce freeze-dried powder, approximately 20 kilograms of fresh acai berries are required to yield 1 kilogram of freeze-dried acai powder.

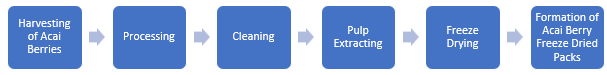

In addition, processing equipment is essential for transforming fresh acai into freeze-dried packs. The process involves several steps, including washing, pulping, and freeze-drying. The freeze-drying process itself requires a vacuum system that operates at low temperatures to preserve the nutrients and flavours of the acai while removing moisture through sublimation. These raw materials are crucial for ensuring the quality of acai berry freeze-dried packs.

Moreover, to help stakeholders determine the economics of an acai berry freeze-dried packs plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

However, challenges such as climate vulnerability and supply chain inefficiencies may threaten the stability of acai berry supplies. Extreme climate change impacts the growth of acai palms, with unpredictable weather leading to fluctuations in harvest volumes. Additionally, the acai supply chain is often fragmented, with 50-60% of production managed by small-scale farmers. This fragmentation results in inconsistent quality and logistical challenges, as fresh berries must be processed quickly to prevent spoilage. To combat these issues, manufacturers of acai berry freeze-dried packs can implement sustainable harvesting practices and invest in improved supply chain management. By fostering stronger relationships with local farmers and promoting eco-friendly initiatives, companies can enhance supply reliability.

Acai berry freeze dried packs are made from the acai fruit, native to the Amazon rainforest, renowned for its high antioxidant content and numerous health benefits. The freeze-drying process preserves the fruit's nutritional properties while extending its shelf life. Acai has been consumed by Amazonian tribes for centuries, but it gained international popularity in the early 2000s, particularly after its introduction to the U.S. market by companies like Sambazon.

Acai berry freeze dried packs typically weighs between 100 to 200 grams and features a fine powder consistency with a deep purple hue, characteristic of the acai berry. The powder is highly soluble in water, making it easy to incorporate into smoothies or beverages. Chemically, the freeze dried acai contains approximately 49.14 g of lipids, 9.19 g of proteins, 20.29 g of dietary fiber, and 2.71 g of sugars per 100 g of freeze dried pulp. It is rich in total phenolic compounds (about 1405 mg gallic acid/100 g) and anthocyanins (around 127 mg cyanidine-3-glucoside/100 g), contributing to its health benefits. The freeze-drying process also enhances the stability of these bioactive compounds, protecting them from degradation during storage.

The production process of acai berry freeze dried packs begins with the harvesting of acai berries from the acai palm trees in the Amazon rainforest. The harvested berries are then transported to processing facilities, typically within 48 hours to prevent spoilage. At the processing stage, the berries undergo cleaning and mechanical processing to extract the pulp. The extracted pulp is then subjected to freeze-drying. The acai berry freeze dried packs is then carefully packaged into vacuum-sealed packs to ensure freshness and extended shelf life.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

The acai berry freeze dried packs market is driven by a growing demand for natural and healthy food products, as consumers become increasingly health-conscious and seek nutrient-rich options. These packs are widely used in a variety of applications, including smoothies, energy bars, and dietary supplements, due to their high antioxidant content and versatility. Companies like Sambazon and Wilderness Poets have introduced innovative products that incorporate freeze dried acai, catering to the rising trend of superfoods. Additionally, the expansion of e-commerce platforms has made it easier for consumers to access these products, further fuelling market growth.

A detailed overview of production cost analysis that evaluates the manufacturing process of acai berry freeze-dried packs is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. For instance, Brazil is the leading region in acai berry production, with the state of Para accounting for over 93% of the country's output. Other significant producers include Amazonas, Bahia, Maranhao, Roraima, and Rondônia. Businesses in the acai berry freeze-dried pack market can improve sourcing by establishing direct relationships with producers in Brazil. Collaborating with local communities fosters goodwill and supports sustainable development. Targeting international markets, such as North America and Europe can expand revenue opportunities as global demand for acai rises.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for an acai berry freeze-dried packs production plant:

Market Dynamics and Trends: Growth factors such as growth of e-commerce and the rise of functional foods significantly affect market conditions in the acai berry freeze-dried packs sector. Online platforms enable customers to order a variety of acai items, including powders, supplements, and ready-to-drink beverages, from the comfort of their homes. Amazon reported a 30% increase in acai berry product sales in 2023 compared to the previous year as e-commerce facilitates a wider selection of acai products. Thrive Market and Sambazon also noted substantial increases in acai berry product sales during 2023. The functional food trend further propels the integration of frozen acai berries into smoothies and energy bars. In fact, in 2023, acai berry-based products accounted for approximately 5-7% of new functional food and beverage releases. Understanding these trends helps businesses align their production plans with demands and trends in the acai berry freeze-dried packs market.

Profiling of Key Industry Players: Leading manufacturers in the acai berry freeze-dried packs sector include several notable companies. Sambazon is known for being the first company to introduce acai to the U.S. market and establishing itself as the largest vertically integrated supplier of acai powders and pulp. Dragon Superfoods is another key manufacturer, providing freeze-dried acai berry powder. Vita Forte Inc. also specialises in high-quality organic freeze-dried acai powder, catering to wholesale and bulk orders. ECOMMODITIES S.A.C. focuses on organic acai products sourced from Brazil, offering various forms including frozen pulp and freeze-dried powder. 100% Amazonia Ltda. supplies a range of acai products, including freeze-dried options. Other significant players in this market include Nimbus Trading, Xingu Fruit, Kshipra Biotech, and Ingredient Brothers.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in the prices of acai berry freeze-dried packs are driven by several key factors, primarily related to supply chain dynamics, production costs, and market demand. One significant factor is the cost of raw materials, particularly acai berries themselves. The high import costs associated with transporting acai berries from Brazil to other regions contribute to elevated retail prices. In 2023, the prices for bulk freeze-dried acai berry powder ranged from approximately USD 5.50 to USD 7.89 per kilogram. Companies like Vita Forte offers organic freeze-dried acai powder at prices between USD 44.50 and USD 60.00 per kilogram for wholesale purchases.

Climate vulnerability poses a challenge as well. Acai palms are sensitive to changes in climate, including variations in rainfall and temperature fluctuations, which can impact both the yield and quality of the berries. Inconsistent harvest volumes due to these climate-induced uncertainties can lead to supply shortages, further driving up prices. Studies indicate that a rise in average temperatures could lead to significant reductions in suitable habitats for acai palms by 2061-2080. This potential decline in suitable growing areas underscores the need for stakeholders in the acai berry market to adapt to these challenges strategically.

Establishing an acai berry freeze-dried packs manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

The establishment of an acai berry freeze-dried packs manufacturing facility must comply with various regulatory frameworks that govern production standards. Key regulations include the Food Safety Modernization Act (FSMA) in the United States, which help to prevent food safety hazards and mandates comprehensive safety plans for food manufacturers. In addition, compliance with the FDA’s Current Good Manufacturing Practice (cGMP) regulations is essential to ensure that products are consistently produced and controlled according to quality standards.

In the European Union, manufacturers must adhere to regulations such as Regulation (EC) No 178/2002, which lays down the general principles and requirements of food law, and Regulation (EU) No 1169/2011, concerning the provision of food information to consumers, including labeling requirements for nutritional content and allergens. Furthermore, if the acai berry products are marketed as organic, compliance with Regulation (EC) No 834/2007 on organic production and labelling is necessary. Compliance with these regulations not only ensures legal operation but also enhances product safety and marketability.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the acai berry freeze-dried packs industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share